Finally, I’m getting around to adding side windows to the Vardo. I’ve wavered for a long time as to whether this was what I wanted. In the end, the ventilation and view won out. Many decisions needed to be made. What kind of opening, size, materials, etc. In the end, I chose reclaimed oak as it is very stable, strong, easy to work with, and looks good.

This isn’t a high-tech, double-glazed thermal window. It is a simple square frame of oak around a Lexan pane with a simple, chromed piano hinge and a nice brass casement window mechanism.

This isn’t a high-tech, double-glazed thermal window. It is a simple square frame of oak around a Lexan pane with a simple, chromed piano hinge and a nice brass casement window mechanism.

The discolored oak is visible here as I didn’t bother to remove the patina from the parts that will be invisible once installed.

The discolored oak is visible here as I didn’t bother to remove the patina from the parts that will be invisible once installed.

I am sometimes criticized here for not giving enough of the remedial steps when building something new… So here it goes:

How to install a window into your Vardo.

First, choose where the window will be placed. I have kept this spot in mind from the beginning and have kept it free of shelves and cubbies. I decided to center the window on the structural stud.

First, choose where the window will be placed. I have kept this spot in mind from the beginning and have kept it free of shelves and cubbies. I decided to center the window on the structural stud.

A blank wall makes exact placement difficult.

A drill hole will mark the center of the window.

I knew where the window needed to be located on the inside, but finding the exact placement on the outside wall can be difficult. In order to find the point on the outside wall, I drilled a small hole where the top center of the window should be. Why did I need to do this? Because the cutting from the outside smooth wall is far easier and less messy (keeping the sawdust mostly on the outside).

Marker hole visible.

Measuring down to locate top of window.

Using the hole as a marker, a line was created to layout the opening.

A framing square was used to square up the other three sides of the opening. The circular saw was used, making a plunge cut (using two hands) as deep as possible, following the guide lines.

Plunge cuts made.

Trusty panel saw makes easy work of it.

The nature of the circular blade prevents the saw from cutting into the corner so a hand-saw was used to finish up.

After a dry fitting to check the size, silicone caulk was applied to seal out water and the window was inserted.

After a dry fitting to check the size, silicone caulk was applied to seal out water and the window was inserted.

Having a look at the new window.

Having a look at the new window.

Checking the functionality. Interior framing is not yet complete here.

Next step… making the shutter.

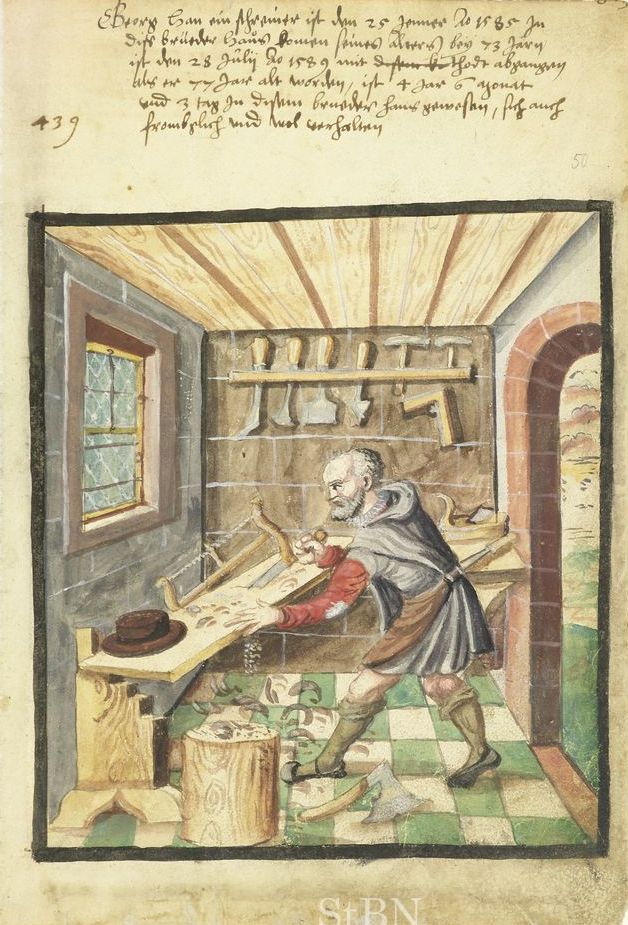

PETER FOLLANSBEE: JOINER’S NOTES