February 1939 magazine advertisement. Ironized Yeast, the quick way to gain weight so you’ll look better in a bathing suit.

Don’t be scorned, get more dates, thicken up.

Oh how things change. Cheap, abundant trash food, and no physical labor.

Adventures of an Imperfect Man In Search of a Handmade Life

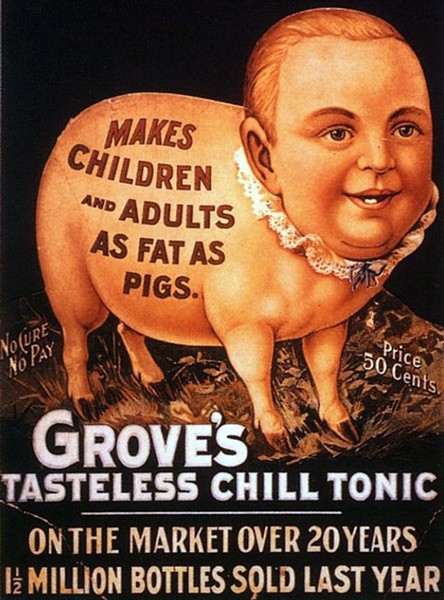

Apparently, this sold better than Coca-Cola in 1890. If only this was our problem now.

Yummy! Its tasteless AND makes you fat.

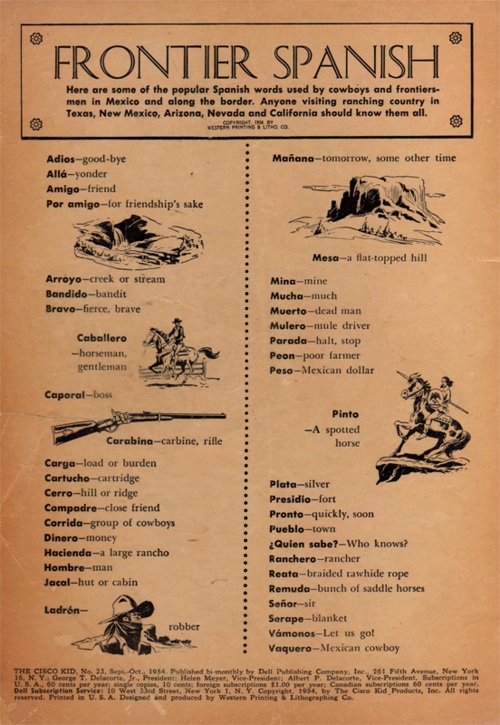

For the monolingual gringos, it never hurts to know more.

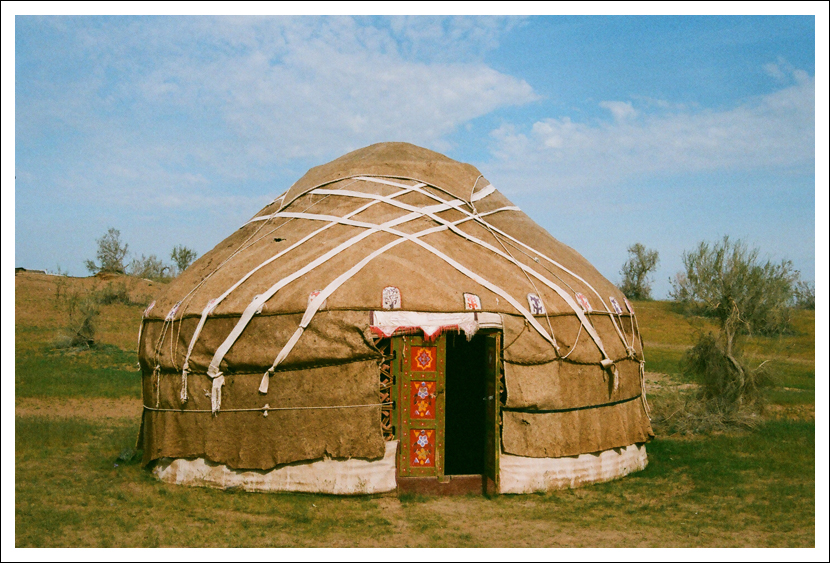

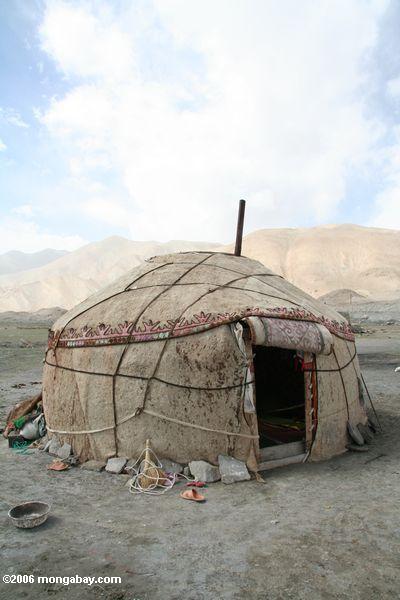

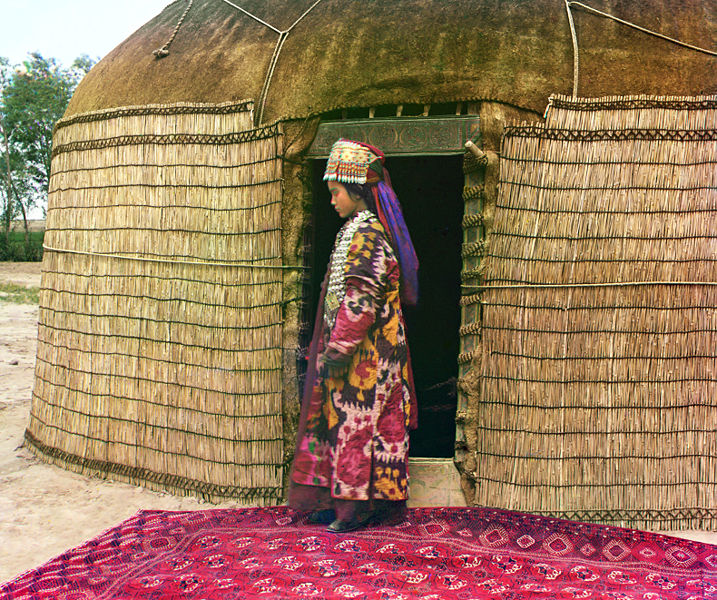

I save images from around the internet to serve as references and inspirations for projects and dreams. I have wanted to build a yurt (ger) for many years now but never quite seem to get around to it. Other projects spring up and I’m not desperate for housing but it is still something floating out there on the edge of my mind. While looking through images, mostly from Tumblr and Flickr, I thought I would share some traditional images I’ve found because I’ll bet I’m not the only one interested. Prior to the internet, I remember very few people knowing what these were unless you were into Asian culture or alternative dwellings, but now they seem to have a great following again. To me, they are a sensible dwelling with very low impact on the earth, can pack down small enough to haul all over the country, yet provide a spacious, weatherproof habitation. If they are constructed of all natural materials there will be little trace when they are abandoned and nothing to overflow the landfills. All of these images are reposted from elsewhere but I have tried to link them to the source where I found them when possible.

I’ll add more when I get the time. Looking at the details fires up my urge to craft a yurt of my own.

Everything you build, every entertainment you make, every meal you procure yourself frees you from the market economy and liberates you a little more from the consumer system.

Take charge of your health – It’s the only body you get.

Eat clean, avoid fake foods, look at ingredients, consume nothing ultra-processed. If there are ingredients listed that you wouldn’t likely have in your pantry, they are not something you need in your body.

Have a great day!

Some shoe solutions from the Bronze Age, North Africa.

Sandal maker – New Kingdom, 18th Dynasty from Thebes ca. 1504–1425 B.C.

Like a Diderot illustration this gives a good insight to the workshop of an artisan with the essentials of his trade. There’s the stool, which is useful in leatherwork as it gives a good lap to work on. A beam, probably implying that the leather is made on-site. A couple of awls in handles are shown and what is probably a curved awl, made from antelope horn, useful when weaving leather (my speculation based on huaracheros and other traditional weaving tools). The sole of the sandal looks to be leather and is being punched with the awl. Other sandals are made from fiber, probably by a different artisan specialist, while burial sandals were likely a specialty industry and are often made from wood or precious metals.

Papyrus fiber sandals. Second Intermediate Period–Early New Kingdom, 17th-18th Dynasty, Thebes ca. 1580–1479 B.C. These are constructed using a coil basketry technique which involves wrapping a soft fiber around a thicker, linear element while “sewing” into the adjacent coil.

Papyrus fiber sandals. Second Intermediate Period–Early New Kingdom, 17th-18th Dynasty, Thebes ca. 1580–1479 B.C.

Red ochre stained calfskin leather sandals. New Kingdom 18th Dynasty during the joint reign of Hatshepsut and Thutmose III ca. 1473–1458 B.C. These are interesting as they are tooled to look like woven sandals. The leather might be harder-wearing but the woven style may have denoted more wealth (i.e., flimsy shoes equates to more wealth or less need to labor). A very simple design used for thousands of years and well-illustrated in the sandal maker panel above. This is a good survival sandal that could be made quickly in the field from many materials today.

Finally, a couple pair of golden burial sandals (women’s) from Thebes, New Kingdom 18th Dynasty during the reign of Thutmose III ca. 1479–1425 B.C. Note the embossing to imitate stitching. A simple design that could be made up in a very short time.

All of the above images are from the Metropolitan Museum of Art, New York and clicking any of the photos will take you to the appropriate page for the artifact. I chose these sandals as I believe the best survival solutions are tried and true and generally exhibited in the archaeological record if the material survives. Make yourself a pair of shoes. With a little practice, basic footwear can be made that is serviceable and fit for public wear. Our ancestors did this for thousands of years, we can too.

Everything you build, every entertainment you make, every meal you procure yourself frees you from the market economy and liberates you a little more from the consumer system.

Here are a couple of photos of the one I still think of as the “new horse.” It is made up of mostly recycled and scrap wood that I was hoarding for just such a project. More than ten years later, I am still quite happy with the size and design of this one. It isn’t perfect for everything, but what is? It has produced bows and darts, spears and walking sticks, and held dozens of other projects along the way. It is a sturdy saw bench and a nice place to sit and have a beer at the end of the day.

The bench itself is made of pine and fir dimensional lumber. The working portions are red oak, white oak, hickory, and popular. The large bolts are salvaged from an old Ford truck spare tire holder.

Here is an update on one of my favorite throwers. It was created one morning from a scrap of Osage Orange wood from the bow-making pile. The finger loops are rawhide. The style is a generalized Basketmaker/Great Basin but is probably a bit heavier than some of the originals as I throw darts that are probably heavier too. It works for me. It has no weight attached yet in the above photo but had one added later just for the “tradition”. It throws well; even with my heavy Paleo darts.

This piece has made me think of longevity of simple tools. Since I made my first thrower in 1987 I have learned much from examination and experimentation. If I used it everyday, I’m certain it would be battered and possibly broken by now. When a spear thrower isn’t being used for its intended purpose, I suspect it would be a club, digging stick, reach pole, or any other purpose that a stick is used for.

“The man who, by his own and his family’s labour can provide a sufficiency of food and raiment, and a comfortable dwelling-place, is not a poor man.”

From: Cottage Economy, William Cobbett 1833.