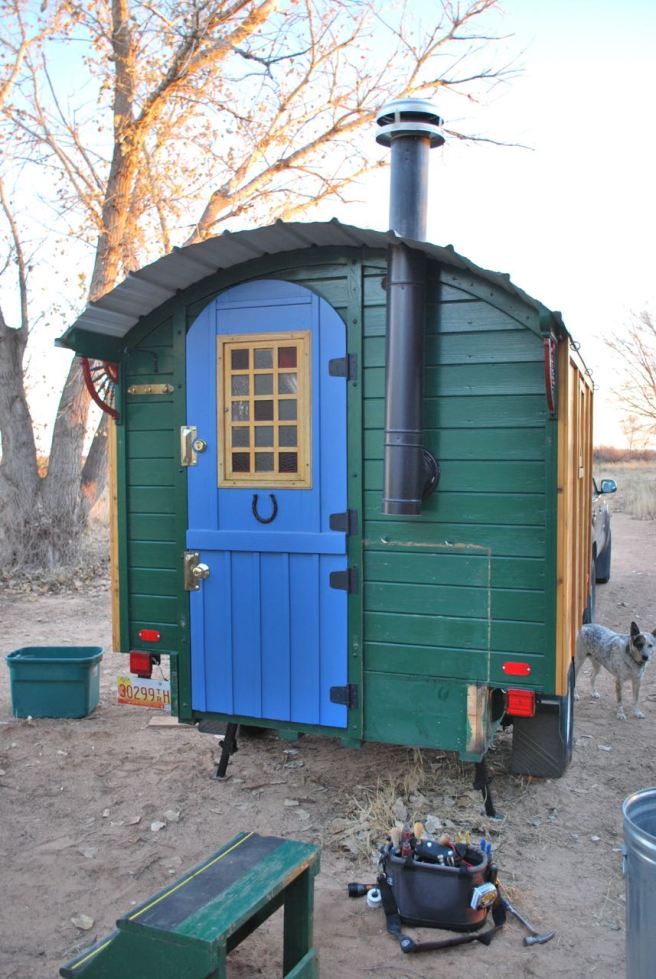

What follows is a somewhat terse step-by-step of the past couple weeks.

I had about a week of stolen moments before the winter holidays to dive in and make as much progress as possible, knowing that winter could bring just about any kind of weather and a 60 degree variance in daily temperatures. My goal was to have the roof covered before bad things could happen. Last minute unexpected issues with work severely limited my time and ability to really focus so it was difficult to stay on track, but being exposed to the elements, the roof was a pressing issue.

Building the wagon from the inside out, you can see the interior tongue and groove pine and the battens that will stiffen the wall and provide a place to mount the cedar siding. As I feared, the arc I cut on the end wall was not perfect and had to be compensated for while setting the purlins (the small beams seen above that will ultimately hold the roof structure). This was a critical phase of measuring, eyeing, and double checking everything because it would be glaringly obvious to the most uncritical eye if the roof-line was not straight. Needless to say, I fretted and tweaked each board until I felt sure from every angle that the alignment was right.

It was about this time that we began hearing a forecast for severe weather, including substantial snow and high winds, in the coming days. This added a real urgency to the need for roofing and wrapping up the current steps.

After tacking down the plywood ceiling, it was time to mark screw locations. A 3/4 inch (ca. 2 cm) purlin is a small target to hit blindly.

A couple near misses with roofing nails were required to get things lined up but once marked, things moved along simply enough.

I didn’t take photos of the roofing paper or waterproof canvas that overlays the plywood but those steps are pretty self-explanatory.

Now it was time to add a strengthening arch to the back wall. After a couple of less-than-exact attempts to create a perfectly matched form from plywood I had a Eureka moment when I decided to use the wagon itself as the form. Cutting a pile of 3/16 inch oak strips, I then glued and clamped them in place overnight. Fortunately, the temperature stayed well above freezing through this entire step. The metal was laid on the roof and tacked down while we hunkered down for the storm

Knowing where I live, and the capriciousness of the weather here, we took the blizzard warnings seriously and wrapped up the entire back half of the wagon in an enormous tarp, attaching it with roofing nails. It was a good thing too. What followed was over 30 hours of straight-line winds from 50-70 miles per hour (80-112 kph) with gusts reported at the nearby Air Force base up to 87 mph (140 kph). Thousands of cattle died in the region and we had structural damage to one of our buildings but the vardo survived.

The cold week that followed was time to take a break, eat, drink, and be merry over the holiday.

Getting back to the task at hand, the roof was finished and cedar planking added to the sides; the ends running long until they are cut into an ornamental shape.

The butt-joint will be covered with another batten to seal the joint.

The weather had stayed cold, limiting some of the work but the need to weatherize the exterior presses on my mind. I’ll be back to the grind in a little while and will update the progress as best I can. Comments are certainly welcome!

If you are looking for Part 1 of the rebuild/addition then CLICK HERE.